◎ Overview

African Swine Fever (ASF) is an acute, hemorrhagic and virulent infectious disease caused by African Swine fever virus (ASFV) infecting domestic pigs and various wild boars (such as African wild boars and European wild boars). It is classified by the World Organization for Animal Health (OIEJ) as a legally reported animal disease and is characterized by a short onset process and a mortality rate of infection of up to 100%.

It was introduced into China in August 2018, and as of April 8, the African swine fever outbreak occurred in all of the country except Taiwan, and the current epidemic is gaining serious momentum. Some of the infected areas are blocked, and the national pig production and pork supply are insufficient. Not only is this true domestically, but the global situation is also dire. since 2019, nearly 2,200 new outbreaks have been reported worldwide in the first three months alone, involving 14 countries. The number of outbreaks and the scope of their impact have increased significantly compared to previous years. The actual situation that pigs are infected with "blind spots" for prevention and control and that there is no safe and effective vaccine worldwide continues to put the global pig industry to the test.

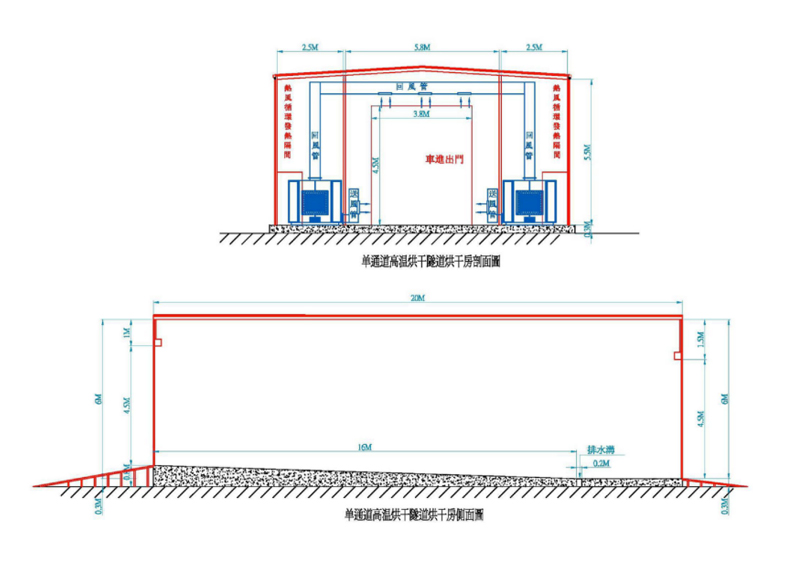

The Ministry of Agriculture and Rural Affairs pointed out that African swine fever can be inactivated in 70℃ for half an hour, so major pig farms must do a good job of prevention and control, and strictly disinfect vehicles and materials entering and leaving pig farms at high temperatures to prevent non-fever, because if one case is infected, the whole farm must be culled at a huge cost. Therefore high temperature disinfection tunnels become especially important and needed, and all major pig farms need to be equipped with decontamination workshops.

◎ Vehicle drying workflow

The objects of disinfection are vehicles and materials, mainly pig and feed transport vehicles and vehicles of admission personnel, other specially developed vehicles, tools, household goods and other materials that can withstand high temperature disinfection, and Transfluence provides a full set of solutions for the above needs.

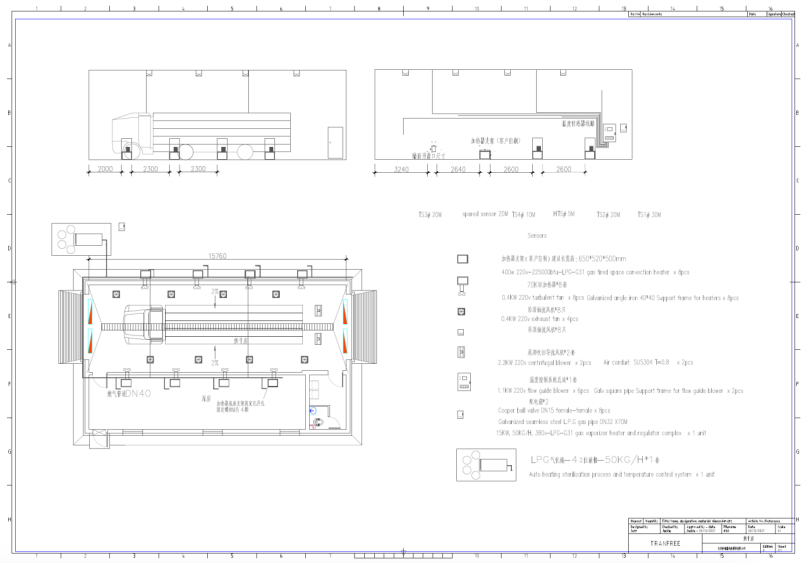

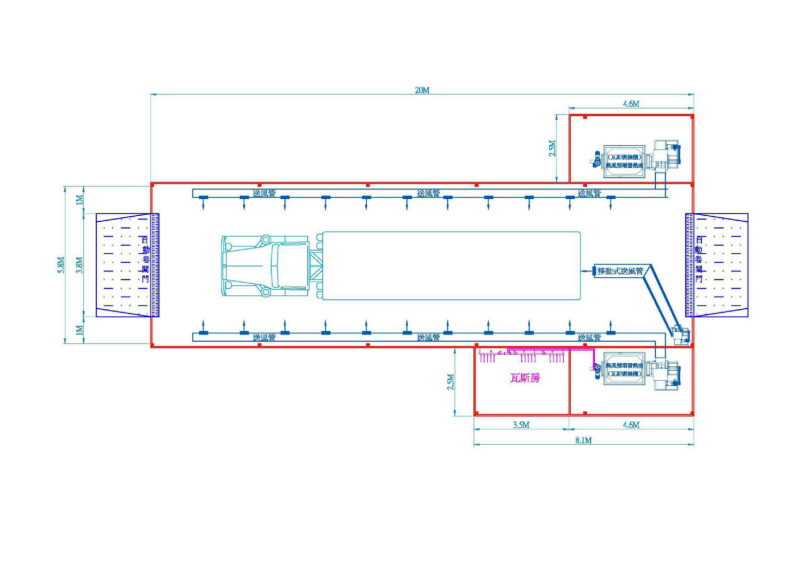

◎ Layout

◎ Program Description

1、Vehicle drying room control function description

(1) vehicle into the drying room, personnel evacuation and close the door, open the control cabinet, display the last set parameter information and enter the work interface, such as no change directly touch the screen "start" button;.

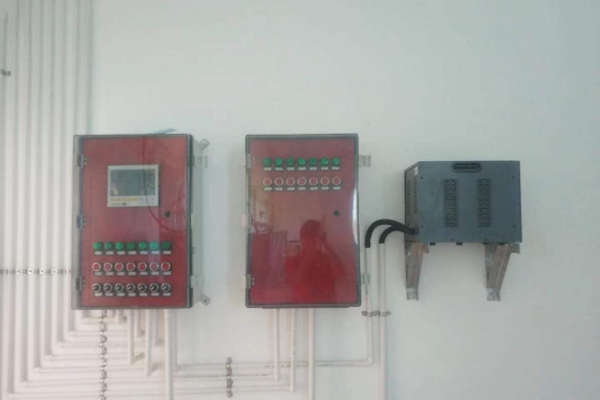

(2) the interface displays eight real-time temperature conditions, touch the "start" button, the control cabinet output signal to the power distribution cabinet to open the fan, heater, the equipment began to work in accordance with the set value;.

(3) The default temperature setting value is 70℃, each probe controls its corresponding heater separately, each probe is independent, when the temperature area corresponding to one or more probes reaches the preset value, the corresponding heater stops working, and the other heating areas still keep heating up.

(4) From the beginning of heating to the temperature reaches 70 ℃ (can be customized according to demand), the timing only starts to count, not reaching the temperature does not time, so that each but area can ensure that the temperature really reaches the temperature before the disinfection continues enough time to ensure the effect of disinfection.

(5) after the end of drying and disinfection, the equipment will automatically shut down the drying and heating system, while storing the drying data, such as the set temperature, drying time, temperature changes with time, humidity changes and so on, these data can be saved for 30 days, can also be exported to print.

2、Vehicle drying room configuration description

(1) 8 top fans run at the same time at the beginning of the heating stage, the rapid heating of the hot air downward pressure, dilution. There are 6 inflow fans at the end, which can send the airflow to 20m distance for blowing the interior of the car. The circulating fans are designed to be controlled independently, and after the heating is finished, they can be turned off manually after the heat dissipation is completed according to the remaining temperature of the room.

Drying heat source consists of eight 70kw gas direct combustion engines, positive pressure air supply, independent start and stop, controlled by the relevant temperature probe, when the temperature reaches, the heater will first turn off the flame and gas, the internal blower will continue to work for one minute to dissipate the residual heat of the body and then enter standby, waiting for the next heating signal.

The fuel is liquefied gas liquid phase gas, equipped with a 50/100kg/h forced heating gasification skid to ensure good working condition for all heaters centralized gas supply.

By a set of integrated environmental control system box and distribution box to control the operation of all equipment.

3、The estimated running cost of vehicle drying room

Drying room operating costs and drying room insulation conditions and vehicle status (humidity, material, full or empty), as well as the external ambient temperature and other factors.

In the southern region, for example, according to the 9.6m box truck, with 35 minutes of drying time (heating 5 minutes, insulation 30 minutes), due to the automatic control of equipment work start and stop, after reaching the temperature out of the standby state, can be calculated in accordance with 30% of the full load of equipment, 35 * 30% = 10.5 minutes, that is, 0.17 hours.

Using LPG as fuel budget, the gas consumption of each unit is 4.9kg/h, drying and disinfecting a car, the total gas consumption of 8 heaters is 4.9*8*0.17≈6.66kg. Depending on the region, the price of liquefied gas generally varies from 6 to 9 yuan/kg, taking the highest price of 9 yuan/kg of liquefied gas, the cost per car is 6.66*9=59.97 yuan, during which other electricity consuming equipment can be budgeted according to 10kw.

◎ Project Case