LPG gas supply unit

LPG supply methods are divided into cylinder gas supply, centralized gas supply in cylinder sets, containerized centralized gas supply, and large storage tank gas supply.

Related products

Natural gas supply method is divided into Dewar tank gas supply, one body skid gas supply, standard station gas supply, gas supply.

The whole machine is made of stainless steel, resistant to high temperature and corrosion

The whole machine adopts high protection design, can work in harsh environment

Introduction to LPG cylinder gas supply

LPG cylinder gas supply is flexible and easy to use. It relies on natural heat absorption and gasification, and the gas supply is small, which is suitable for temporary heating use. When customers purchase a single machine, they can directly use the high and medium pressure pressure reducing valve that comes with the equipment to directly supply gas to the LPG cylinder for heating, i.e. connecting, opening and heating, and the quick heating method provides great convenience to the small area heating demand.

Simple gas supply system (small gas cylinder):

| Cylinder specification (kg) | Number of configured cylinders (pcs) | Number of available heaters* (units) | Working hours* (hours) | Output pressure range (kPa) |

| 15 | 1 | 1 | 2.5 | 3-3.7 |

| 50 | 1 | 1 | 9.5 | 3-3.7 |

| 50 | 2 | 2 | 19.8 | 3-3.7 |

*Take PA70 type heater as an example

LPG micro centralized gas supply station

LPG micro centralized gas supply station is a gas supply device developed to solve the demand of small and medium-sized gas supply. The customer connects the purchased gas cylinders to the manifold at one time, and the gas enters the gasifier through the manifold, and after gasification, it is transported by pipeline to the gas heater of pig house, drying room and other gas points. According to the demand of gas supply, there are specifications of different gasification volume from 30kg~200kg for customers to choose.

Centralized gas supply station for LPG cylinder sets.:

| Micro sled specifications (kg/h) | Configuration 50kg cylinder number - liquid phase (one) | Power supply parameters (kW) | Number of available heaters* (units) | Dimension (mm) | Output pressure range (kPa) |

| 30 | 2 | Single-phase-3 | 6 | 1200*400*1050 | 50-70 |

| 150 | 3 | Three-Phase-8 | 10 | 1380*520*1070 | 50-70 |

| 100 | 4 | Three-Phase-15 | 20 | 1600*580*1300 | 50-70 |

| 150 | 5 | Three-Phase-21 | 30 | 1800*600*1400 | 50-70 |

| 300 | 6 | Three-Phase-27 | 40 | 2200*600*1600 | 50-70 |

*Take PA70 type heater as an example

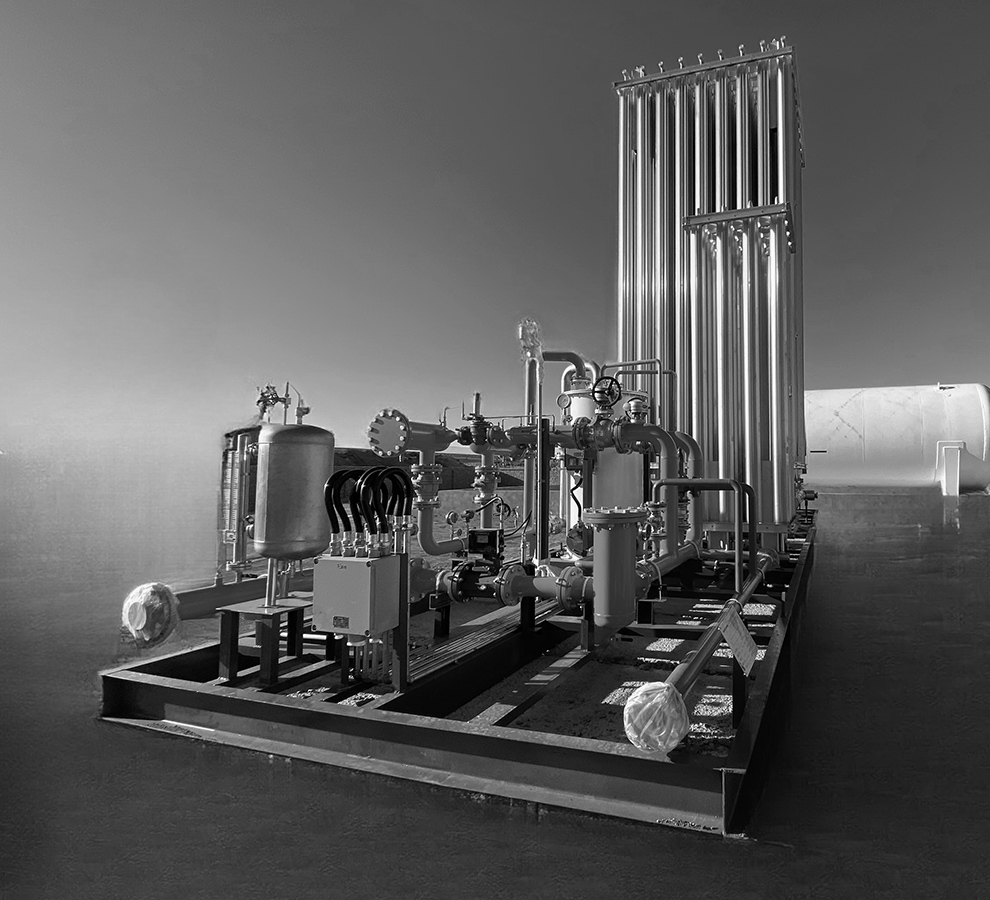

Containerized gas supply station

The containerized gas supply station is an upgraded integrated equipment compared with the micro gas supply station. In addition to having a larger gas supply capacity, it also has an independent bottle group room and gasification room, which can save the cost of building an equipment room, and the containerized gas supply unit is equipped with safety facilities such as combustible gas leakage alarm, liquid phase automatic switching device, forced exhaust and fire extinguishing device from the factory to fully meet the fire fighting requirements. Depending on the amount of gas used by customers, custom designs can be made from 8 to 32 bottle sizes to provide customers with a stable and economical clean heating solution. The number of bottles is chosen based on the consideration of gas consumption, combined with the economy and convenience of obtaining gas sources.

Container gas supply station:

| LPG skid (kg/h) | Configuration 50kg cylinder quantity (pcs) | Power consumption (kW) | Number of available heaters* (set) | Dimension (m) | Skid net weight (ton) |

| 100 | 8-32 | 15 | 15-20 | 2*4 3*8 | 1-2 |

| 150 | 8-32 | 23 | 20-30 | 2*4 3*8 | 1-2 |

| 200 | 16-32 | 30 | 30-40 | 3*8 | 2-2.5 |

| 300 | 16-32 | 45 | 40-60 | 3*8 | 2-2.5 |

*Take PA70 type heater as an example